Day#1

The natural yeast leiven, and the soaker

Day #2- have all the final dough ingredients weighted and ready. Prep the ingredients for the mechanical mixing. Mix the final dough, with the goal of achieving a soft cohesive dough ball that is slightly tacky and just about passes the window pane test. Bulk fermentation until 1 1/2 times the volume is achieved.

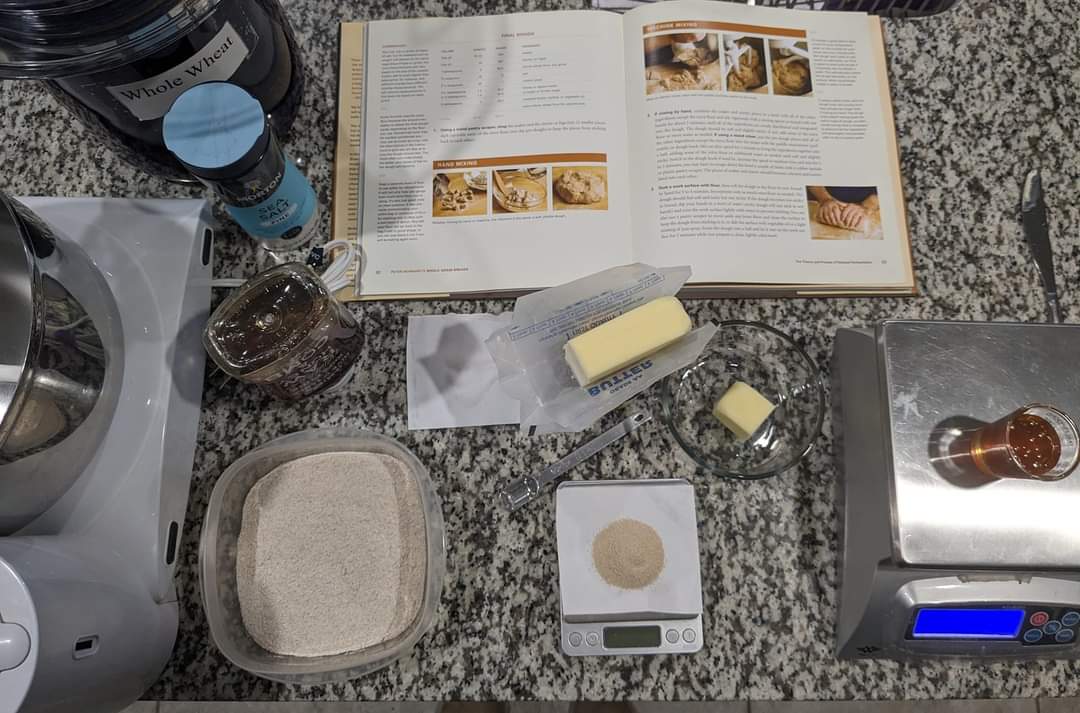

The final dough ingredients at the ready.

Final dough ingredients are prepped for the mixing

The dough after one minute at Bosch speed #1

After an additional two minutes at Bosch speed #2, the dough is very tacky. That being said, it just about passes the window pane test.

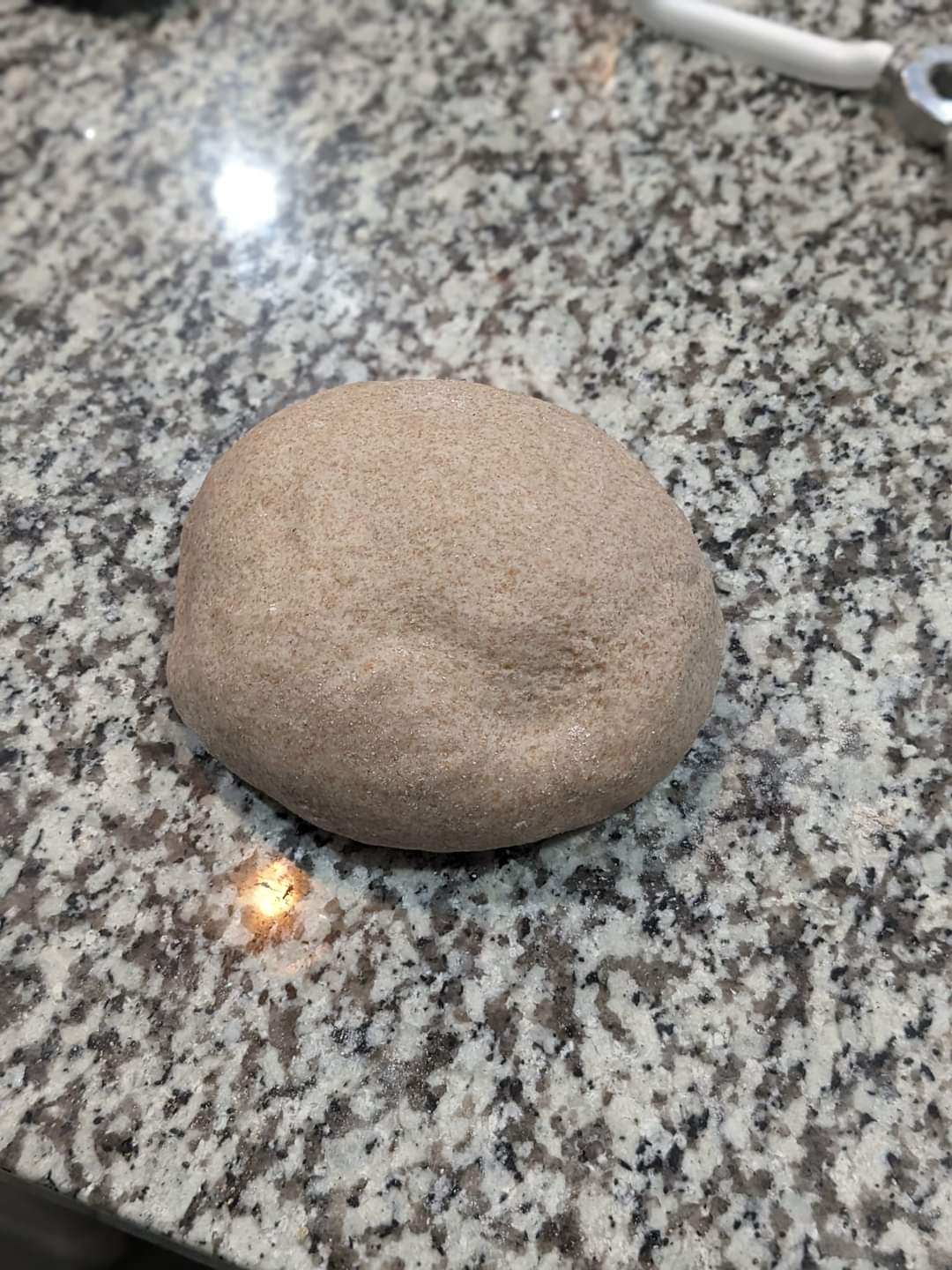

Straight out of the mixer. The dough came out clean. It required only a minimumal amount of bench flour. After just two hand kneads the dough ball is gaining strength.

After only ten or so nana style hand kneads, the dough is looking shiny, soft, and just a bit tacky.

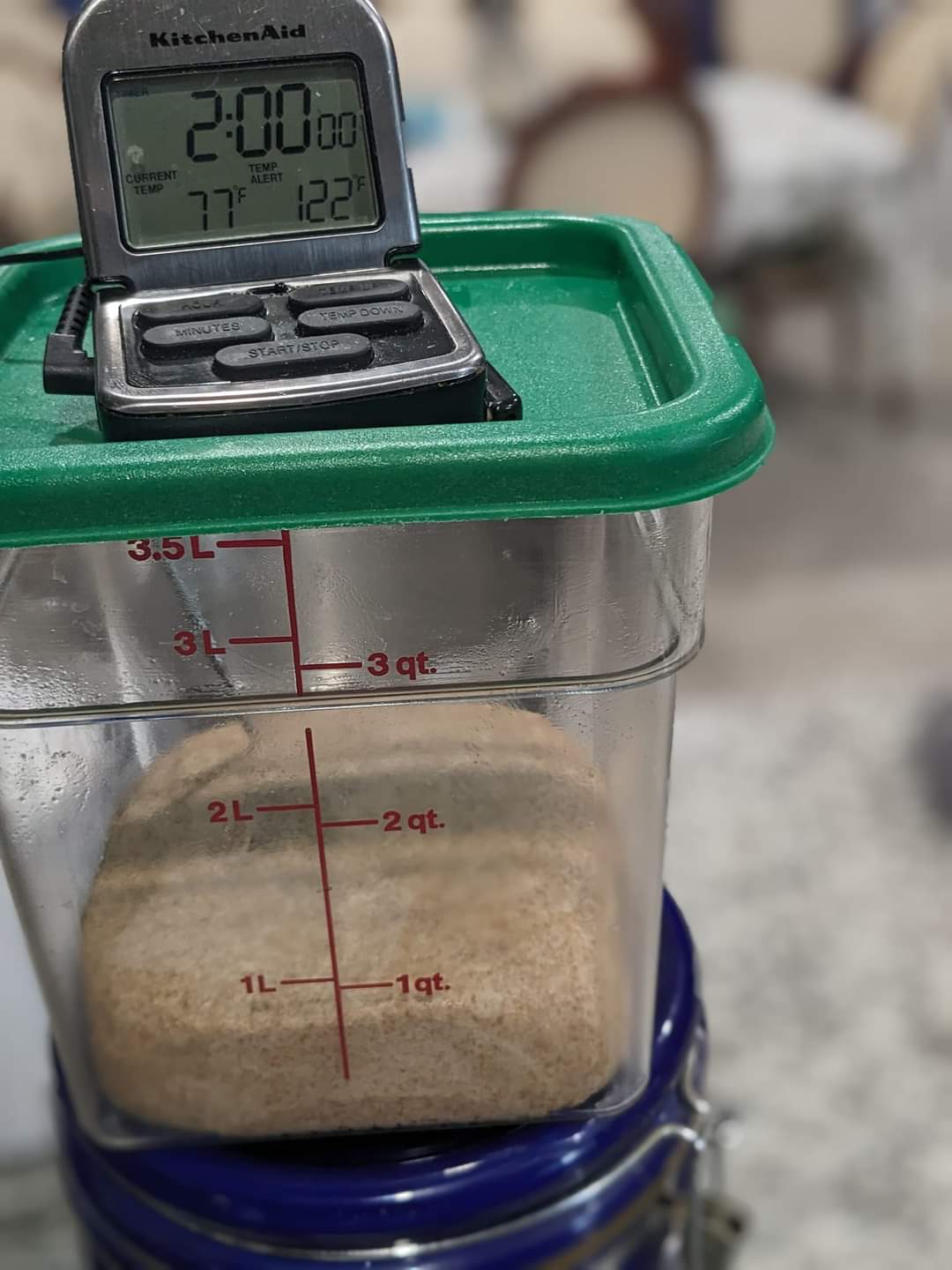

Bulk fermentation is initiated.

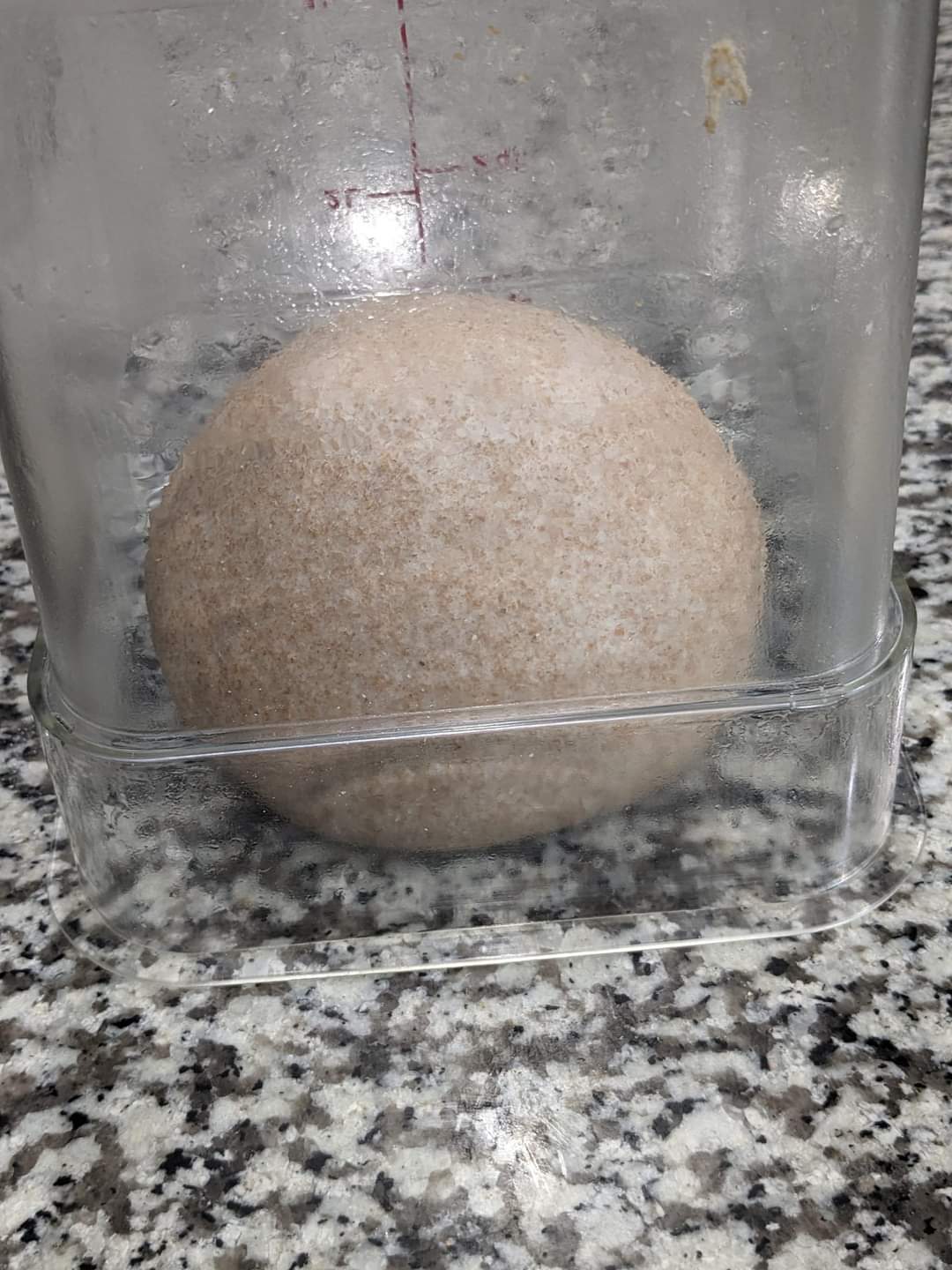

After 1:15 the dough ball is gaining volume. However, the target has not yet been achieved. Ambient temperature inside the fermentation container 78°F.

After a total of 1:45 the volume goal increase is achieved.

The dough ball is preshaped using bench resistance. Then a ten minute rest, before the final shaping.

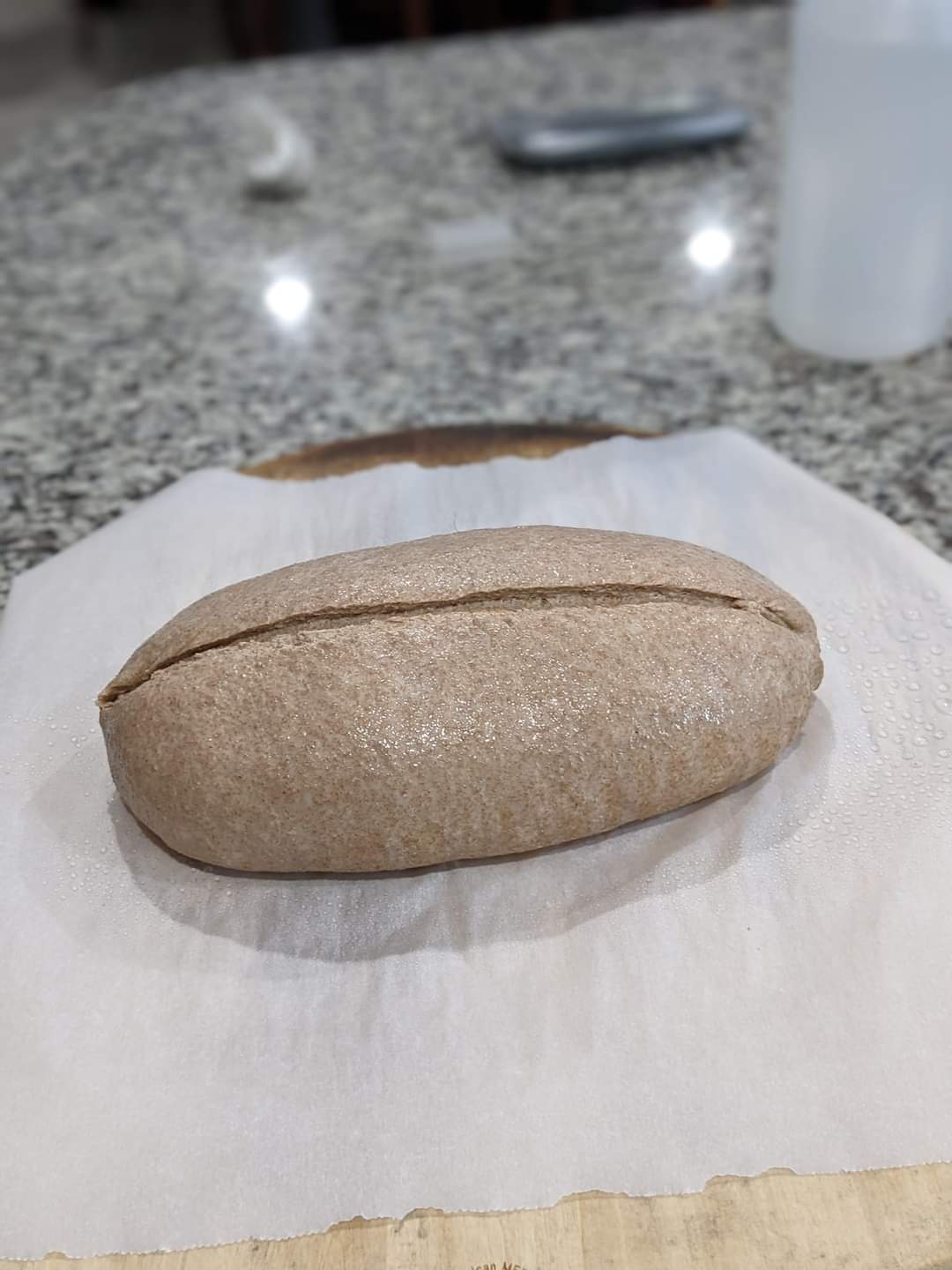

The pre-shaped dough ball is shaped into a batard, with a nice tight skin. The shaped batard is put to proof. Oven, (preheat 550°F) and steaming apparatus are ready

45 minutes of proofing,and the poke test reveals a slightly under proofed batard. Moving on to the end game score, and bake.

Conclusion:

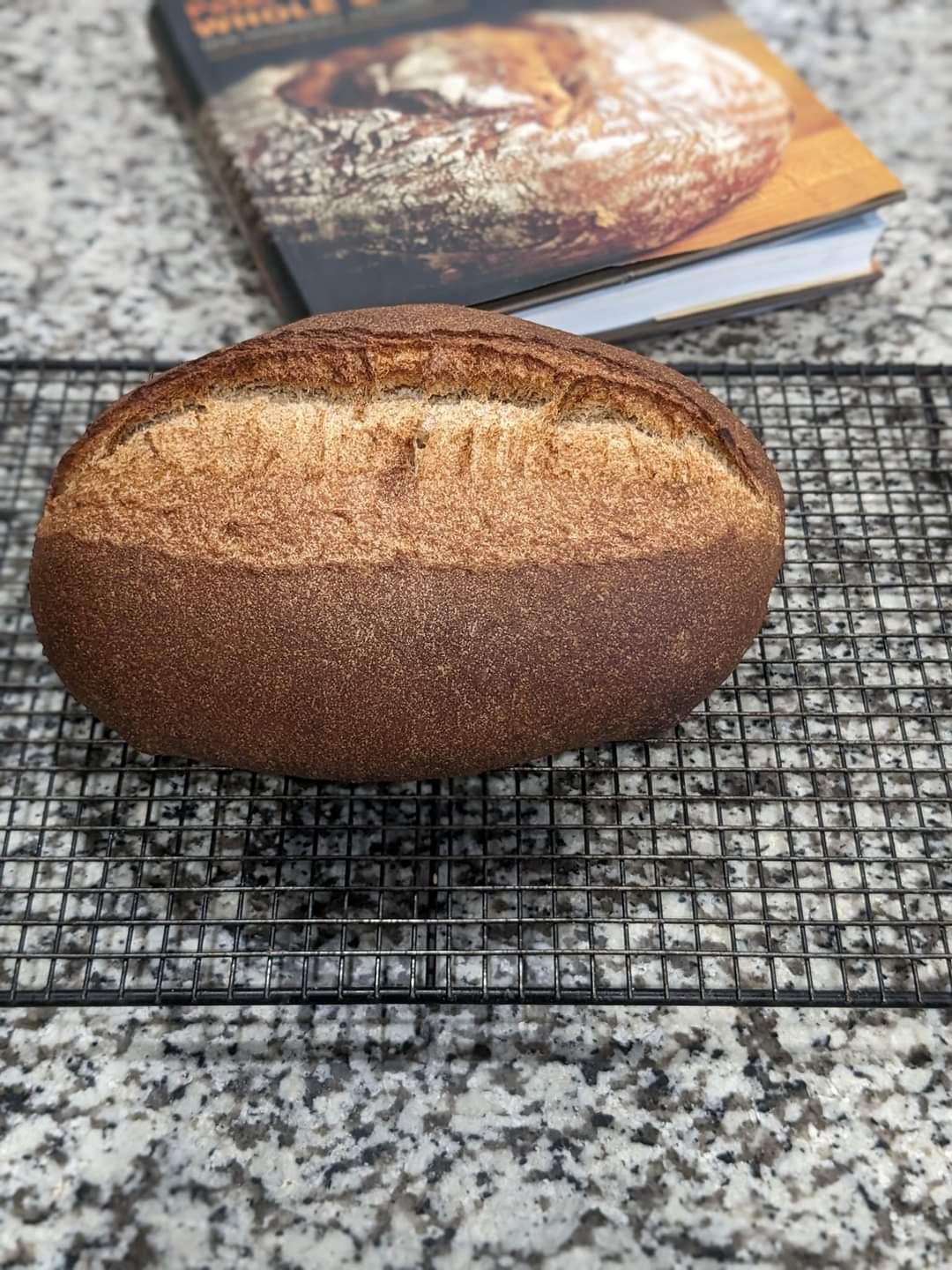

Everything about this bake is wonderful.

1. The dough was surprisingly user friendly, and easy to handle. What a pleasure.

2. For all intents and purposes no adjustments were needed during any of the stages. Out of the mixer maybe 1/2 a teaspoon of flour that made its way on to the bench was used. No extra water. No wet hands needed

3. Did I mention the oven spring? Remember, this is 100% whole wheat, with inclusions too! Amazing formula. The master formula, that only a master could develop.

3. The rich dark mahogany color is making it very hard to let this beauty cool properly. However, I will exercise restraint.

Special thanks to Mariana, a knowledgeable, excellent baker in her own rite for pointing me to a part of whole grain breads, I otherwise would have passed up. For sure I would have went straight to the formula section.

That concludes another live play by play bake. Thanks for reading.

Your friend,

Will Falzon